Table of Contents

At Melt-to-Make™, we’ve partnered with Tanis, the industry leader in gummy equipment, to bring you Scalable Gummy Manufacturing with Tanis and Melt-to-Make™—a seamless solution for businesses looking to scale efficiently and produce high-quality gummies with ease.

By combining Tanis' cutting-edge equipment with our All-Natural Melt-to-Make™ Gummy Bases, we’ve eliminated the guesswork from gummy production, giving you a streamlined, cost-effective path to high-quality results. Whether you're looking to increase capacity or refine your process, our partnership with Tanis.com ensures you have the tools and expertise to grow efficiently without compromising quality.

Melt-to-Make™ Gummy Bases 🤝 Tanis Cooking Systems

When it comes to gummy manufacturing, efficiency and consistency are key. That’s why Melt-to-Make™ Gummy Bases pair seamlessly with Tanis Cooking Systems, offering a streamlined, scalable solution for businesses looking to increase production without compromising quality.

With Melt-to-Make™, you eliminate the need for complex formulation and ingredient sourcing, allowing you to focus on creating unique, high-quality gummies. Our pre-formulated, all-natural Gummy Bases are designed to integrate effortlessly into professional cooking systems like Tanis, ensuring a smooth, efficient process from start to finish.

When working with Melt-to-Make, there are a few different gummy bases to choose from:

Peach - 10kg Case - Melt-to-Make® Pectin Gummy Base

$249.00

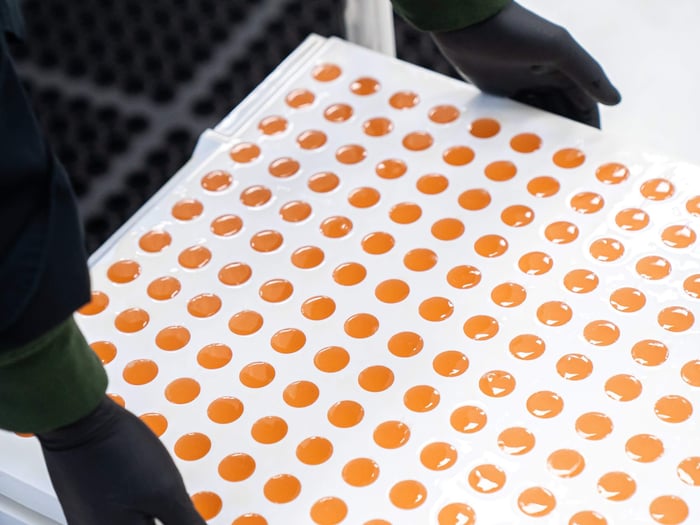

A naturally sweet and juicy Peach Pectin gummy base. Finished gummies will have a light orange appearance. Due to pigment variation of natural colors, a slight color difference might be observed between batches. … read more

Mango - 10kg Case - Melt-to-Make™ Sugar-Free Pectin Gummy Base

$299.00

A naturally sweet and juicy Mango Sugar-Free Pectin Gummy Base. Finished gummies will have a vibrant orange appearance. Due to pigment variation of natural colors, slight color difference might be observed between batches. … read more

Tanis Cooking Systems are known for their precision, reliability, and ease of use, making them the perfect match for Melt-to-Make™ Gummy Bases. Whether you're just starting out or looking to scale up your production, this combination provides a turnkey solution that helps you save time and money, reduce labor, and optimize efficiency—all while producing consistently great-tasting gummies every time.

Watch this video and discover how easy it is to manufacture gummies efficiently with Melt-to-Make™ Gummy Bases and Tanis processing machinery.

Tanis 400S NS Semi Automatic Depositor

The Tanis 400S NS is an ideal solution for businesses seeking a reliable entry point into scaling their gummy production. With a 20-liter hopper capacity, this depositor ensures precise and efficient operation providing you with a solid foundation to grow your gummy manufacturing business. By utilizing this depositor with Melt-to-Make™ Gummy Bases, you'll be able to increase your production capacity by 50% or more, reaching an impressive output.

400S NS System Features

The Tanis 400S NS supports the use of flexible silicone molds as a stand-alone option, or hygienic polycarbonate molds that can be seamlessly integrated as your production scales. This system features ensures precise and consistent piece weights while achieving an impressive production rate of 10,000 to 30,000 pieces per hour!

Check out this video for insights on operating the Tanis 400s NS!

Cooling and Demolding with Tanis

When producing gummies at high volumes, investing in a cooling and a demolding machine can be a game-changer as well. Tanis offers an excellent solution for both cooling and demolding that can speed your process and keep your production days running at peak performance. Their conditioning system allows for up to 140 - 180 moulding trays, while also controlling temperature, airflow, and humidity. After your gummies have cured in the molds, you can simply place the mold into the demolding system. The demoulding machine uses a hygienic vacuum system to effortlessly release the gummies, which are then gently deposited into a bin below—eliminating the need for manual handling and saving valuable time.

Check out the video below to see how Tanis' demoulding system works!

The Final Step: Sanding Sugar or Wax Coating?

To complete your high-quality gummies, Tanis offers advanced coating systems that provide the final touch to your products. Whether you’re looking for a sugar or wax coating, Tanis has the right solution to ensure your gummies meet the highest standards of quality, consistency, and visual appeal. These systems are designed for high-volume production, ensuring that each piece is evenly coated and ready for packaging.

If you have any questions about Scalable Gummy Manufacturing with Tanis and Melt-to-Make™, don’t hesitate to contact Tanis or our team here at Melt-to-Make™ for more information and personalized assistance. Tanis' team is highly knowledgeable and can guide you through the features and benefits of their equipment to help you find the best solution for your production needs. Whether you're scaling up operations, enhancing efficiency, or maintaining hygienic standards, Tanis and Melt-to-Make™ can provide expert advice and tailored options to suit your gummy manufacturing needs.

Melt-to-Make™ Contact

1-800-241-0341 // support@melt-to-make.com

Tanis Contact

info@bainbridge-assoc.com

FAQs

What is Scalable Gummy Manufacturing with Tanis and Melt-to-Make™?

Scalable Gummy Manufacturing with Tanis and Melt-to-Make™ is a turnkey solution that combines Tanis’ world-class gummy processing equipment with Melt-to-Make™’s all-natural gummy bases. Together, they offer businesses an efficient, consistent, and reliable way to scale gummy production without compromising quality or flavor.

Why partner with Tanis for gummy manufacturing?

Tanis is an industry leader in gummy cooking, depositing, and conditioning systems. Their machinery—known for precision, reliability, and hygiene—integrates seamlessly with Melt-to-Make™ Gummy Bases. This partnership eliminates the complexity of formulation and equipment compatibility, making it easier to expand production efficiently.

What makes Melt-to-Make™ Gummy Bases ideal for scaling production?

Melt-to-Make™ Gummy Bases are pre-formulated, all-natural, and ready to use, removing the need for complex ingredient sourcing or formulation. They’re designed to flow perfectly in professional cooking systems like Tanis, helping manufacturers produce consistent, great-tasting gummies with minimal setup time.

What is the Tanis 400S NS Semi-Automatic Depositor?

The Tanis 400S NS Semi-Automatic Depositor is a reliable entry-level system for businesses ready to scale gummy production. It features a 20-liter hopper capacity, supports both silicone and polycarbonate molds, and offers a production rate of 10,000 to 30,000 pieces per hour—boosting efficiency by 50% or more when paired with Melt-to-Make™ Gummy Bases.

How does the cooling and demolding process work with Tanis equipment?

Tanis’ cooling and demolding systems streamline post-production by precisely controlling temperature, airflow, and humidity. The hygienic vacuum demolder releases gummies effortlessly, eliminating manual handling and ensuring consistent product quality—an essential step for large-scale production.

Can I add sugar or wax coatings to my gummies using Tanis systems?

Yes! Tanis offers advanced sanding sugar and wax coating systems designed for high-volume operations. These systems ensure each gummy is evenly coated for optimal texture, visual appeal, and product consistency—perfect for finishing your Melt-to-Make™ gummies.

Who should consider using Tanis and Melt-to-Make™ for gummy manufacturing?

This solution is ideal for large brands, contract manufacturers, and confectionery startups looking to expand production capacity, improve consistency, and simplify operations. Whether you’re scaling up or refining your process, Tanis and Melt-to-Make™ offer the technology and formulation expertise to support your growth.