Table of Contents

Drying Your Melt-to-Make™ Gummies

In this blog we'll be going over how to dry and coat gummies when using Melt-to-Make™ Gummy Bases. Properly drying your gummies is essential for ensuring they are shelf-stable and maintain their quality. This is why we’ve created the ultimate guide to drying and coating gummies, helping you achieve perfect results every time.

The gummy drying process not only determines the final texture of your gummies, but also significantly impacts their shelf stability by preventing issues like stickiness, melting, or premature spoilage. A well-executed drying procedure removes excess moisture, which helps to limit microbial growth, maintain the gummies' shape, prevents them from "sweating", and enhances their overall texture.

Water Activity Level

Additionally, the drying process allows the gummies to reach the proper water activity level—a key factor in overall shelf life. By achieving the right level of water activity, your gummies will resist unwanted changes in quality, flavor, and texture over time. Failing to dry them properly can lead to inconsistent results, reduced shelf life, or quality concerns. With that said, when you successfully dry your gummies while also using Melt-to-Make™ all-natural Gummy Bases, you're presented with the best gummy on the market!

Melt-to-Make™ Drying Guide: How to Dry and Coat Gummies

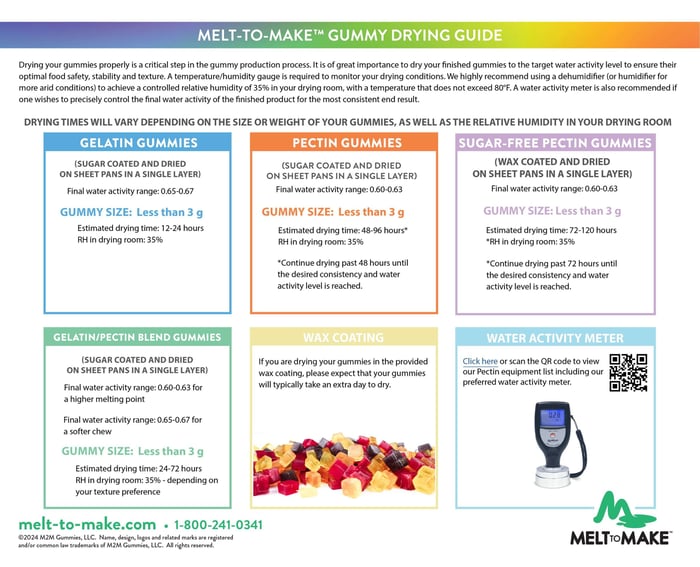

As part of our commitment to quality and ensuring the best possible results for our customers, we offer a comprehensive gummy Drying Guide specifically tailored to all Melt-to-Make™ users. This guide is designed to help you navigate the drying process with ease, ensuring that each batch of gummies is expertly prepared and ready for packaging. It covers everything from ideal drying environment parameters to the optimal drying time and water activity level suggestions, so you can achieve the best texture and consistency for your gummies.

Carnauba Wax vs. Sanding Sugar

At Melt-to-Make™, we provide two coating options for gummies: Sanding Sugar or our Carnauba Wax Coating.

Sanding Sugar is the most popular choice in the cannabis and hemp industries, offering a classic, sweet finish that customers love. At Melt-to-Make™ we offer the option of Conventional Sanding Sugar or Organic Sanding Sugar to finish your gummies. We also have sour booster packs if you’d like to try a sour sugar coating.

Carnauba Wax Coating (which also contains MCT Oil), on the other hand, is the preferred option for nutraceutical and pharmaceutical companies, providing a smooth, glossy coating without added sugar. It's a slightly more health conscious alternative, which is perfect for supplement manufacturers.

If you're aiming to reduce sugar content, make gummies with Melt-to-Make™'s Sugar-Free Pectin Gummy Base, or you're just looking for a different coating option, our Carnauba Wax Coating is the perfect choice. It's ideal for those looking to achieve a professional finish without compromising on quality.

Blueberry - 10kg - Melt-to-Make™ Sugar-Free Pectin Gummy Base

$299.00

Craft a naturally sweet and juicy Blueberry Sugar-Free Pectin Gummy Base with a vibrant bluish-purple hue. Each batch produces gummies with consistent color, though slight variations may occur due to the natural pigment differences.… read more

Our all-natural Carnauba Wax Coating is available with either our Classic Pectin Gummy Bases or Sugar-Free Pectin Gummy Bases, ensuring you have a solution that meets your specific needs. Whether you're creating indulgent treats or functional edibles, we've got you covered!

Unflavored - 550kg Tote - Melt-to-Make® Pectin Gummy Base

$5,500.00

Ready to bring your unique gummy vision to life? With our Unflavored Melt-to-Make® Pectin Gummy Base, creating your own signature flavors and colors has never been easier. Simplify your manufacturing process and craft all-natural gummies that are truly your own. Maximize… read more

How to Apply Melt-to-Make™ Carnauba Wax Coating to Gummies

Melt-to-Make™ Wax Coating Calculator

To start, open up the Melt-to-Make™ Wax Coating Calculator found in the resources section of our website. Once that’s open you’ll want to weigh out the gummies you’re planning to coat, and enter that number into the 'batch size' cell. The calculator will then tell you exactly how much wax you’ll need. Add your gummies and wax to a bowl, and coat them evenly.

Corn Starch + Wax Coating

Another option for coating your gummies is to use corn starch before waxing. Coating your gummies with corn starch before applying wax gives them more of a matte finish instead of a glossy finish. To determine the right amount of corn starch, simply open the second tab in the Wax Coating Calculator, and enter your batch information. Then, evenly coat your gummies in the corn starch and finish by applying the Carnauba Wax Coating.

Once you’ve coated your gummies with the wax, spread them out on trays to dry until they reach the ideal water activity level. For the best results, make sure to check out our gummy Drying Guide in the resources section of our website.

If you have any other questions on how to dry and goat gummies, feel free to reach out to us at support@melt-to-make.com. Your success is our success, and we're here to help with every step of the process!

FAQs

Why is proper gummy drying so important?

Properly drying your gummies is essential for shelf stability, texture, and product quality. The drying process removes excess moisture, limits microbial growth, and prevents issues like stickiness, sweating, or melting. It also helps maintain the desired chewiness and flavor profile, ensuring your gummies look and taste great long after production.

What is water activity, and why does it matter for gummies?

Water activity (Aw) measures the amount of free moisture in your gummies — and it’s one of the biggest factors in determining shelf life and quality stability. Achieving the proper water activity level prevents spoilage, preserves flavor, and maintains texture. Melt-to-Make™ Gummy Bases are formulated to help you reach the ideal balance quickly and reliably.

How can I make sure my gummies reach the proper water activity level?

Follow the Melt-to-Make™ Drying Guide, which provides recommended temperature, humidity, and time parameters for each gummy base type. Monitoring water activity with a calibrated meter ensures that every batch reaches a safe and stable level before packaging.

What coating options does Melt-to-Make™ offer?

We offer two premium coating options:

Sanding Sugar: A sweet, classic coating popular in the cannabis and hemp industries. Available in both Conventional and Organic versions, with optional Sour Booster for tangy finishes.

Carnauba Wax Coating: A smooth, glossy, sugar-free finish preferred by nutraceutical and supplement brands. Made with MCT Oil for even coating and enhanced visual appeal.

Which coating should I use for my gummies?

It depends on your product goals:

Choose Sanding Sugar for a sweet, traditional candy-style gummy.

Choose Carnauba Wax Coating if you want a sugar-free, professional, polished finish — ideal for wellness, nutraceutical, or pharmaceutical products.

If you’re using our Sugar-Free Pectin Gummy Base, we highly recommend pairing it with the Carnauba Wax Coating for best results.

How long should gummies dry before coating?

Drying times vary depending on humidity, airflow, and base type. Use our Melt-to-Make™ Drying Guide for reference. As a general rule, gummies should be fully set and slightly tacky before coating to ensure proper adhesion and even drying afterward.

Where can I find Melt-to-Make™ drying and coating resources?

Visit our Resource Hub to access:

The complete Melt-to-Make™ Drying Guide

Wax Coating Calculator

Formula Calculators and Work Instructions

Educational videos and troubleshooting support

Need extra help? Contact us anytime at support@melt-to-make.com — our technical team is always ready to guide you through your drying and coating process.