Table of Contents

Premium Gummies Made Simple: Melt-to-Make™ Partners with EVOCAN Systems

At Melt-to-Make™, our mission has always been clear: help brands and creators make premium gummies, simply and consistently. That’s why we’re so excited to share more about our partnership with EVOCAN Systems, a leader in innovative gummy manufacturing equipment. Together, we’re making it easier than ever to scale gummy production without sacrificing quality.

EVOCAN is dedicated to developing reliable, efficient, and scalable solutions for the gummy industry. Their equipment is designed to help businesses of all sizes—whether you’re just starting out with small batches or managing large-scale operations—produce gummies with precision and ease.

Breaking Down EVOCAN’s Product Offerings

EVOCAN offers a range of equipment that fits seamlessly into any stage of gummy manufacturing, pairing perfectly with Melt-to-Make™ Gummy Base.

- Tabletop Depositor (20-40 kg per hour)

- Mini Depositor with Cooker (20-40 kg per hour)

- DH-30 (up to 30 k gummies per hour)

- EVOMini (up to 450 kg per hour)

- Evo-300 (up to 120,000 gummies per hour)

- EVO600 + EVOCAN Advanced Solutions

EVOCAN Systems Tabletop Depositor

The EVOCAN Tabletop Depositor is a compact, precision-engineered machine built for confectioners who want professional-grade results without committing to large scale, industrial equipment.

With a production capacity of 20-40 kg per hour and servo-driven accuracy, it ensures consistent deposits every time—minimizing waste and maximizing quality. Ideal for small-to-medium operations, the Tabletop Depositor features a user-friendly interface, quick-change nozzles, and easy-clean components, making it perfect for fast-paced environments that require flexibility. Whether you’re launching a new product or scaling existing lines, this depositor empowers teams to innovate without compromise. Compact, reliable, and cost-effective—it’s a small machine with serious impact.

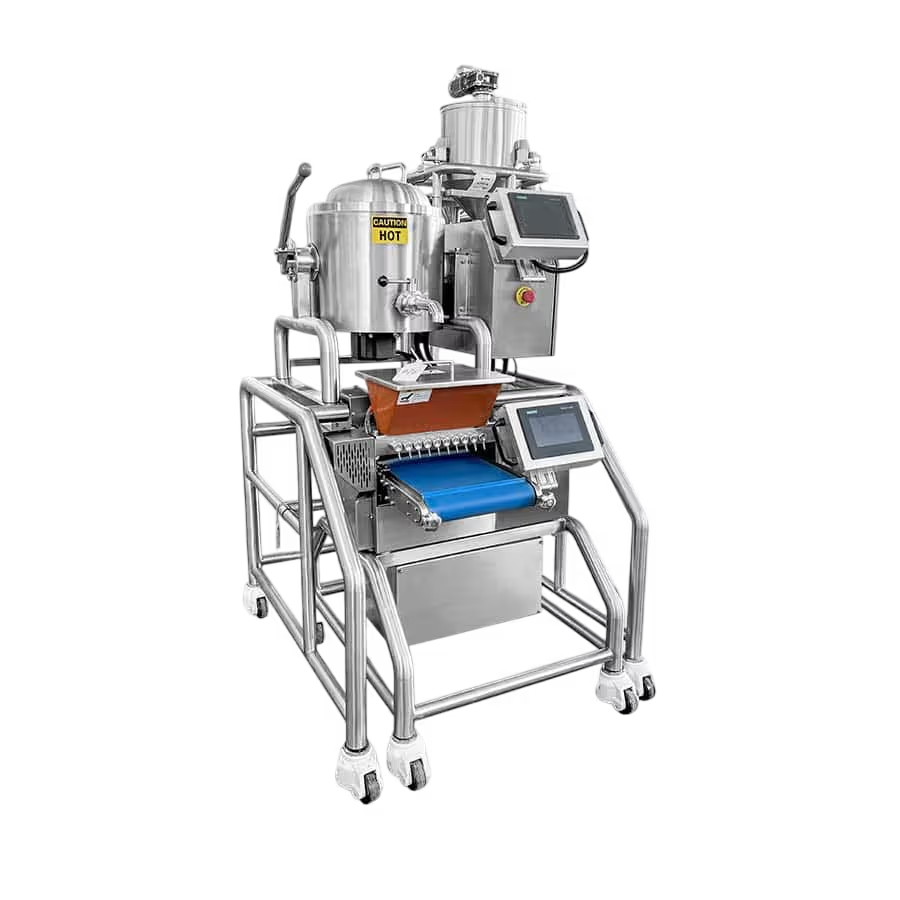

EVOCAN Systems Mini Depositor with Cooker

The EVOCAN Mini Depositor with Cooker is an all-in-one solution designed for low-output production environments, ideal for businesses that want to automate without sacrificing flexibility. Capable of producing up to 20–40 kg/hour, its integrated cooking and depositing functions streamline the gummy manufacturing process, reducing the need for multiple machines and minimizing setup time.

With a small footprint and user-friendly interface, the Mini Depositor with Cooker is a wise, space-efficient choice for facilities looking to scale production while maintaining quality and control.

Running Melt-to-Make™ Gummy Bases Through the

Running Melt-to-Make™ gummy bases through the EVOCAN Tabletop Depositor or Mini Depositor with Cooker is ideal for brands working with smaller quantities — like our 10 kg gummy buckets. These compact systems allow you to create precise, high-quality gummies quickly and efficiently without the need for large-scale equipment.

Watermelon - 10kg Case - Melt-to-Make® Pectin Gummy Base

$249.00

Classic watermelon hard candy flavor without all the artificial ingredients! Finished gummies will have a light pink appearance. Due to pigment variation of natural colors, slight color difference might be observed between batches. … read more

Mango - 10kg Case - Melt-to-Make™ Sugar-Free Pectin Gummy Base

$299.00

A naturally sweet and juicy Mango Sugar-Free Pectin Gummy Base. Finished gummies will have a vibrant orange appearance. Due to pigment variation of natural colors, slight color difference might be observed between batches. … read more

EVOCAN Systems DH-30

The EVOCAN Dual Hopper Depositing System is built for flexibility and efficiency, allowing manufacturers to produce two-color or dual-flavor gummies in a single run. This versatility opens the door to a wider variety of products without the need for additional equipment.

Its compact, space-saving design eliminates the footprint of multiple machines by consolidating functionality into one streamlined system—ideal for facilities with limited floor space. The dual hopper setup also supports quick and easy changeovers between recipes, flavors, or candy types, significantly reducing downtime and boosting production efficiency. Whether you're crafting layered gummies, striped candies, or color-separated treats, this system delivers precision and speed with every batch.

EVOCAN Systems EVOMini

The EVOMini is the fastest compact gummy depositor (for it's size) available at EVOCAN Systems, producing up to 450kg of gummies per hour with exceptional speed and precision. Its compact, advanced design, featuring an intuitive touch-screen HMI, offers an ideal solution for manufacturers aiming to scale production efficiently without sacrificing quality or space.

The EVOMini is the fastest compact gummy depositor (for it's size) available at EVOCAN Systems, producing up to 450kg of gummies per hour with exceptional speed and precision. Its compact, advanced design, featuring an intuitive touch-screen HMI, offers an ideal solution for manufacturers aiming to scale production efficiently without sacrificing quality or space.

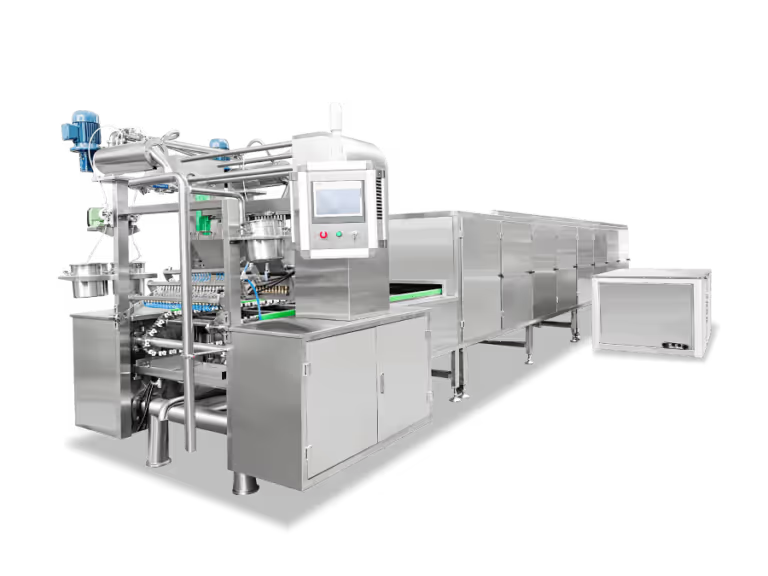

EVOCAN Systems EVO300 Automatic Gummy Production System

The EVO300 Automatic Gummy Production System is a high-capacity, stand-alone gummy production solution engineered for reliability and efficiency. Capable of producing up to 120,000 gummies per hour, it is specifically designed to meet the demands of large-scale operations without compromising precision or consistency.

With its fully automated depositing system, the EVO 300 supports a wide range of gummy shapes, sizes, and colors, offering confectioners the flexibility to diversify their product lines. From pectin and gelatin-based formulas to multi-color or center-filled designs, this system delivers consistent results at scale—ideal for manufacturers looking to streamline production, reduce labor dependency, and boost output.

Running Melt-to-Make™ Gummy Bases Through the

For those manufacturing with our 500 kg Classic Pectin Totes or Sugar-Free Pectin Totes, EVOCAN’s larger machinery offers the speed and capacity needed for high-volume output, making it easy to grow your gummy business while maintaining consistency and control.

Unflavored - 550kg Tote - Melt-to-Make® Pectin Gummy Base

$5,500.00

Ready to bring your unique gummy vision to life? With our Unflavored Melt-to-Make® Pectin Gummy Base, creating your own signature flavors and colors has never been easier. Simplify your manufacturing process and craft all-natural gummies that are truly your own. Maximize… read more

Unflavored - 550kg Tote - Melt-to-Make™ Sugar-Free Pectin Gummy Base

$7,150.00

Ready to bring your unique gummy vision to life? With our Unflavored Melt-to-Make™ Sugar-Free Pectin Gummy Base, creating your own signature flavors and colors has never been easier. Simplify your manufacturing process and craft all-natural gummies that are truly your own.… read more

The Versatility of EVOCAN Systems

One of the biggest advantages of EVOCAN Systems is their versatility. While they pair seamlessly with Melt-to-Make™ gummy bases, their depositor technology isn’t limited to gummies alone. These systems can be adapted for a wide range of confections—from hard candies to jellies, toffees and beyond—making them a smart investment for brands that want flexibility in their production line. Whether you’re focused on scaling gummies or exploring new product formats, Evocan’s equipment gives you room to innovate.

The Power of Partnership: Melt-to-Make™ + EVOCAN Systems

When paired with our Melt-to-Make™ Gummy Bases, EVOCAN's equipment truly shines. Our bases are formulated for consistency, clarity, and taste, meaning less time troubleshooting and more time creating premium products. Combine that with Evocan’s technology, and you’ve got a turnkey solution that simplifies the entire process—from gummy base to finished gummy.

Whether you’re making your first batch or looking to scale into nationwide distribution, this partnership was built to grow with you.

LeafyPack + PlanIt Packaging - Taking it to the Next Level

To take things one step further, EVOCAN Systems is also connected with LeafyPack and PLAN IT PACKAGING - leading companies in packaging automation. Their advanced packaging solutions integrate seamlessly with EVOCAN’s gummy equipment, creating an end-to-end system that handles everything from gummy depositing to precise packaging. This partnership ensures that brands not only produce high-quality gummies with Melt-to-Make™ Gummy Bases, but can also efficiently deposit and package them for retail-ready distribution.

The Difference Between LeafyPack + PlanIt Packaging

LeafyPack

LeafyPack focuses primarily on cannabis and infused edible packaging automation. Whether you need pre-roll, bagging, jar filling, labeling, cartoning, or case packing, LeafyPack offers highly tailored, end-to-end solutions for this niche market.

PlanIt Packaging

- PlanIt Packaging offers broad packaging machinery solutions across sectors—food, beauty, healthcare, snacks, confectionery, pet care, and more.

Whether you’re making your first batch or looking to scale into nationwide distribution, this combined ecosystem of Melt-to-Make™, EVOCAN Systems, PLAN IT PACKAGING and LeafyPack was built to grow with you.

FAQs

Who is Evocan Systems?

Evocan Systems is a leader in innovative gummy manufacturing equipment. For more information, visit their website to explore their product offerings.

How do I know if Evocan equipment is Right for my manufacturing process?

Evocan Systems offers gummy manufacturing equipment for every stage of growth—from tabletop depositors for small-batch or R&D production, to fully automated systems for large-scale operations. If you’re looking for consistent results, efficiency, and the ability to scale without sacrificing quality, Evocan equipment paired with Melt-to-Make™ gummy bases is a strong fit.

What types of gummy equipment does Evocan Systems provide?

Evocan Systems offers tabletop depositors, semi-automated systems, and fully automated depositing equipment. Each option is designed to help manufacturers improve precision, reduce labor, and streamline gummy production. They also have another company by the name of LeafyPack, who supplies advanced packaging and processing systems.

Does Evocan equipment work with Melt-to-Make™ gummy bases?

Yes! Evocan equipment has been tested with Melt-to-Make™ gummy bases to ensure smooth depositing, vibrant colors, and consistent texture. Together, they create a turnkey solution for premium gummy manufacturing.

Is Evocan equipment suitable for small businesses or startups?

Absolutely. The tabletop depositor is perfect for startups, R&D labs, or brands making the jump from hand-pouring molds. As your business grows, Evocan’s semi-automated and fully automated systems make it easy to scale production.

How does Evocan Systems help manufacturers scale up?

Evocan equipment is built for efficiency and consistency, reducing production errors and saving labor costs. When combined with Melt-to-Make™ bases, brands can easily move from small-batch runs to high-volume manufacturing without reworking their entire process.

What is the difference between LeafyPack and PLAN IT PACKAGING?

LeafyPack is the premier designer, supplier, and manufacturer of advanced automation and processing equipment in the cannabis industry. LeafyPack proudly serves niche sectors within the agricultural, confectionery, and plant-derived product industries across North America and select global markets.

Located in Canada, PlanIt Packaging specializes in delivering top-tier packaging system solutions across various sectors, from the dynamic food industry to the intricate landscape of medical technologies.